Lifting System For Precast Concrete Manufacturer

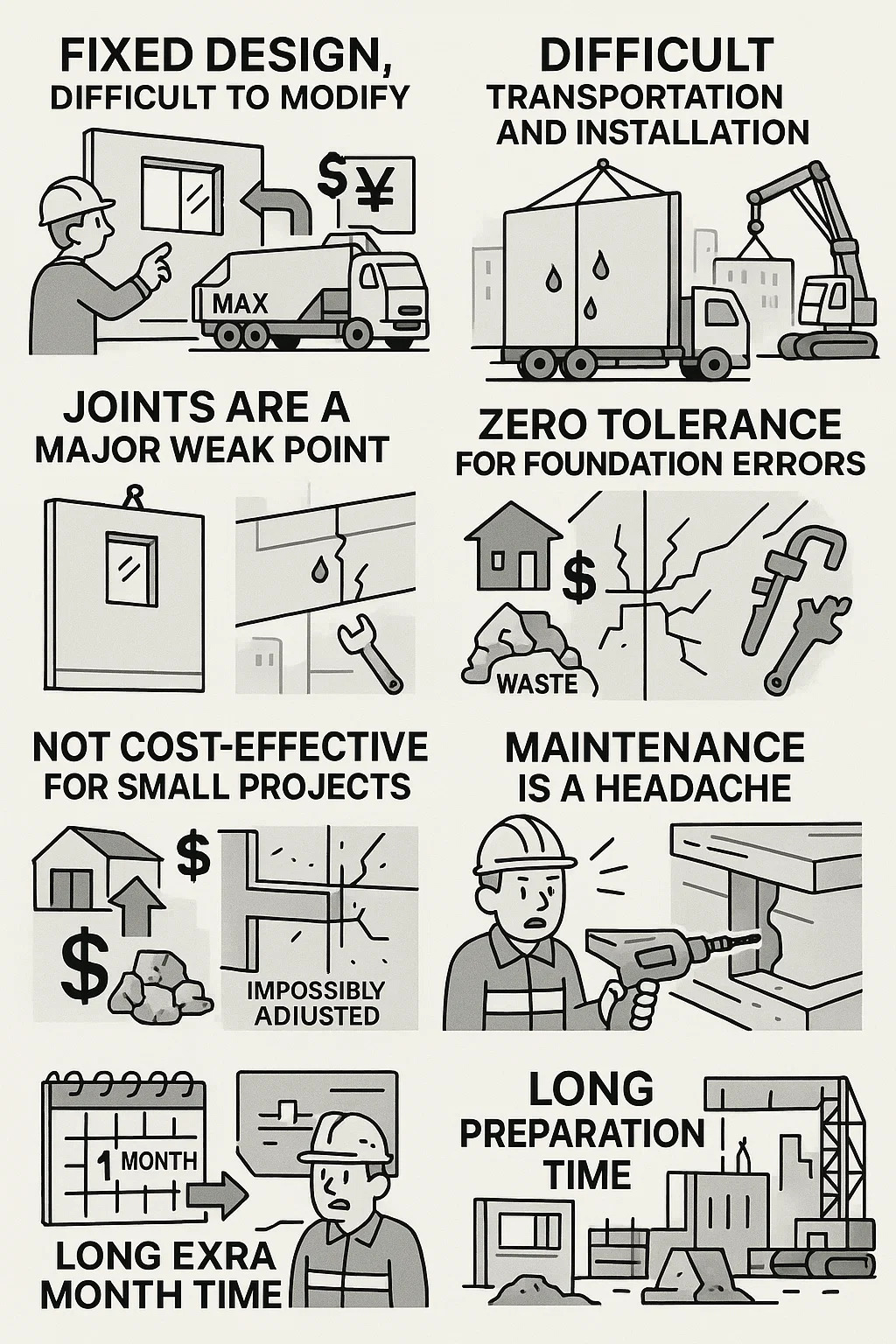

Here are some common drawbacks of precast concrete in practical applications:

Content

1. Fixed Design, Difficult to Modify

High Mold Costs: Each steel mold requires specialized molding. If the window position is changed midway through the design process, the entire mold set may need to be scrapped and remade.

Strict Size Limitations: The maximum size of components is limited by transportation constraints (e.g., a truck cannot carry a 4-meter-wide wall panel), making complex shapes impossible.

2. Difficult Transportation and Installation

Large Components Difficult to Move: Extra-long beams and large wall panels require specialized trucks. Detours are necessary when encountering height restrictions or underpasses, making transportation costs more expensive than the materials themselves.

High Lifting Requirements: Insufficient space for large cranes? They cannot be used in narrow alleys or old residential areas, necessitating the use of cast-in-place concrete.

3. Joints are a Major Weak Point

Prone to Leaks: Joints between wall panels and floor slabs rely entirely on sealant. If the sealant ages or is not applied properly, leaks occur, requiring wall chiseling for repairs.

High Earthquake Resistance: During earthquakes, component joints are prone to cracking and detachment, posing a higher risk than monolithic cast-in-place structures.

4. Zero Tolerance for Foundation Errors

The foundation must be accurate: Even a 2cm deviation in the pre-embedded bolts will cause the entire column to misalign with the hole, requiring on-site hole enlargement or rework at the factory.

On-site remediation is difficult: If the dimensions of components are found to be incorrect upon arrival, it's impossible to adjust them on-site by cutting reinforcing bars as with cast-in-place construction.

5. Not Cost-Effective for Small Projects

Small quantities, high unit price: Just building a small warehouse? The formwork cost alone is 30% higher than cast-in-place.

Waste of Scrap Materials: Factory generally doesn't recycle the concrete waste left over from cutting irregularly shaped components.

6. Maintenance is a Headache

If it breaks, the whole piece must be replaced: If a truck damages a corner of a precast wall, it cannot be repaired locally; the entire section must be dismantled and replaced.

Difficult to Modify Piping: Want to add a water pipe to a precast floor slab? It requires drilling holes and grooves, potentially damaging the internal reinforcing bars.

7. Long Preparation Time

Long design cycle: All details must be finalized before construction begins, and drawings must be repeatedly checked, taking an extra month compared to cast-in-place construction.

Supply chain stability is crucial: Factories are operating at full capacity? Just wait, missing even one board will bring the entire construction site to a standstill.