Can the use of insert magnets simplify the fixing process of concrete inserts?

Yes, the use of insert magnets can greatly simplify the fixing process of concrete inserts.

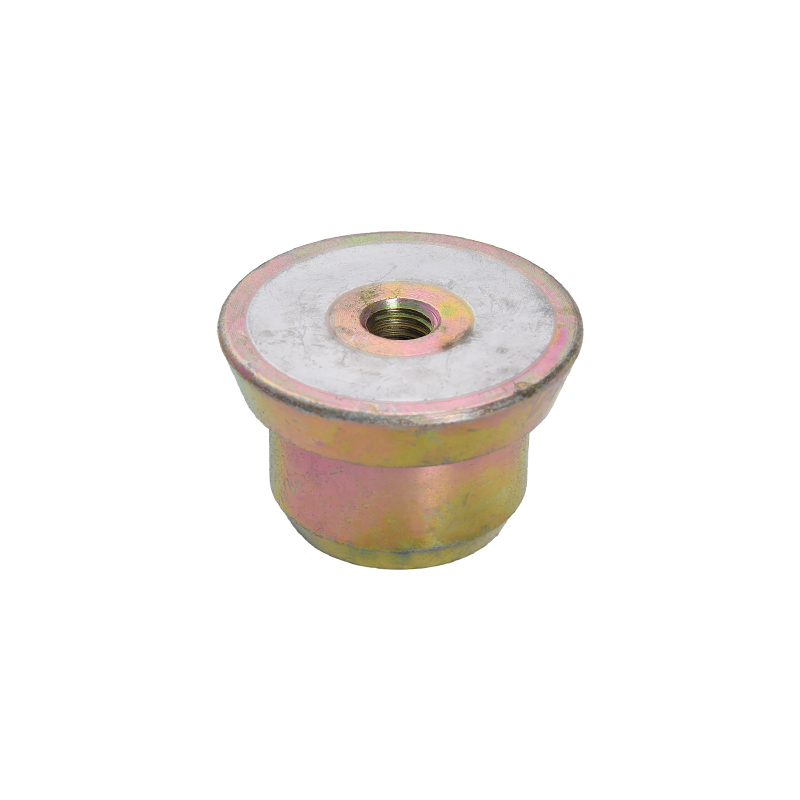

The insert magnet utilizes strong magnetism to easily fix on the magnet template system or steel platform, forming a stable and accurate positioning point. Before pouring concrete, these magnets are pre placed on the formwork or steel platform to ensure their accurate position. When concrete is poured into the template, the insert magnets form free spaces that are used to accommodate and secure concrete inserts, such as steel bars, pipes, or other embedded parts.

The traditional method of fixing concrete inserts may require the use of additional fixing devices or tools, such as fixtures, bolts, etc. These operations are not only cumbersome, but may also increase the cost and time of manual operations. By using insert magnets, it is easy to place them in the predetermined position and fix the inserts through concrete pouring. This method greatly simplifies the fixed process, improves work efficiency, and reduces the errors that may be caused by human operations.

Can I use insert magnets to ensure that the concrete inserts are positioned exactly as they should be?

Yes, using an insert magnet can ensure the accurate position of the concrete insert.

Insert magnets play a crucial role in the positioning of concrete inserts. Due to their strong magnetism, they can firmly adhere to the magnetic template system or steel platform, ensuring that the position of the inserts remains fixed during the concrete pouring process. This fixing method not only reduces the risk of movement or displacement of concrete inserts during the pouring process, but also improves the overall quality and stability of the concrete structure.

In addition, the accuracy of insert magnets is usually very high, ensuring that the position of the insert in the concrete is accurate to the millimeter level. This makes the use of insert magnets an ideal choice in concrete structures that require high-precision positioning, such as bridges, tunnels, high-rise buildings, etc.

Therefore, the use of insert magnets can ensure the accurate position of concrete inserts, improve the stability and durability of concrete structures.

Do insert magnets require additional fixtures?

Insert magnets usually do not require additional fixing devices.

They utilize their strong magnetism to directly adsorb onto the magnetic template system or steel platform, forming a stable and precise positioning point. This magnetic fixing method greatly simplifies the installation process and reduces reliance on additional fixing devices.

However, in certain special circumstances, to ensure the stability and safety of the insert magnet, additional fixing measures may need to be taken according to specific application scenarios and requirements. But this situation is not universal. In most cases, the insert magnet itself is already stable and reliable enough to be used directly without the need for additional fixing devices.