Lifting System For Precast Concrete

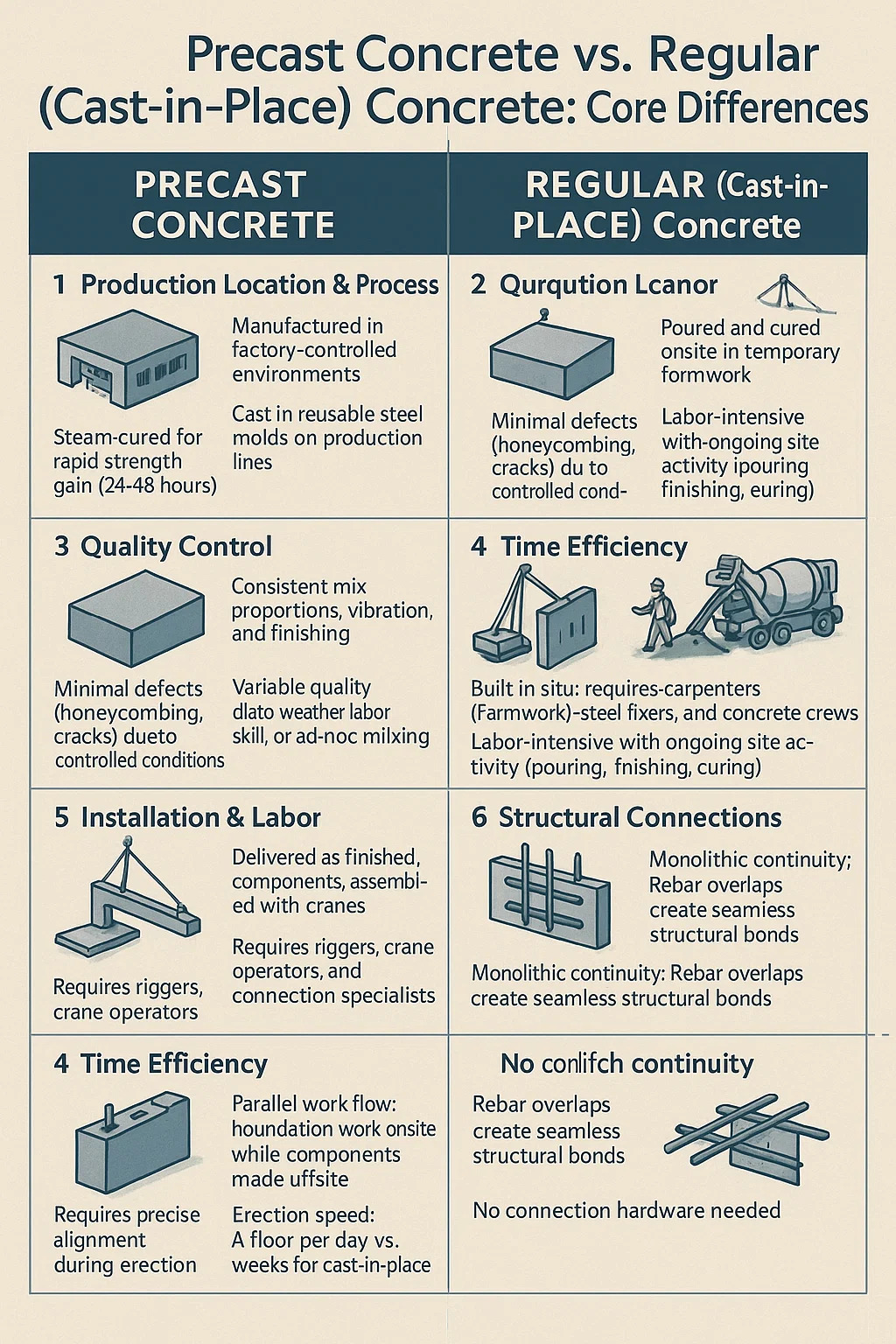

Precast Concrete vs. Regular (Cast-in-Place) Concrete: Core Differences

1. Production Location & Process

Precast:

Manufactured in factory-controlled environments.

Cast in reusable steel molds on production lines.

Steam-cured for rapid strength gain (24-48 hours).

Regular:

Poured and cured onsite in temporary formwork (wood/steel).

Cures naturally over days/weeks, exposed to weather.

2. Quality Control

Precast:

Consistent mix proportions, vibration, and finishing.

Minimal defects (honeycombing, cracks) due to controlled conditions.

Regular:

Variable quality due to weather, labor skill, or ad-hoc mixing.

Risk of cold joints, poor consolidation, or curing issues.

3. Installation & Labor

Precast:

Delivered as finished components; assembled with cranes.

Requires riggers, crane operators, and connection specialists.

Regular:

Built in-situ: requires carpenters (formwork), steel fixers, and concrete crews.

Labor-intensive with ongoing site activity (pouring, finishing, curing).

4. Time Efficiency

Precast:

Parallel workflow: Foundation work onsite while components made offsite.

Erection speed: A floor per day vs. weeks for cast-in-place.

Regular:

Linear workflow: Formwork → rebar → pour → cure → strip forms.

Weather delays extend timelines significantly.

5. Structural Connections

Precast:

Relies on mechanical joints (bolts, welded plates, grouted sleeves).

Requires precise alignment during erection.

Regular:

Monolithic continuity: Rebar overlaps create seamless structural bonds.

No connection hardware needed.

6. Design Flexibility

Precast:

Limited to standardized shapes (costly custom molds).

Hard to modify after production.

Regular:

Unrestricted shapes/sizes (formwork built onsite).

Adjustable during construction.

7. Site Impact

Precast:

Clean, quiet sites; minimal waste/rework.

Heavy transport access and crane pad space required.

Regular:

Noisy, messy sites (formwork, mixing, pumping).

Flexible for confined or remote locations.

8. Cost Drivers

Precast:

High factory/mold costs; economical for repetitive projects.

Savings from reduced labor/time onsite.

Regular:

Lower upfront costs; expensive for complex/long-duration jobs.

Labor, formwork, and delay risks increase expenses.

9. Durability & Finish

Precast:

Superior surface finishes (architectural textures, exposed aggregates).

Optimized curing → denser, more durable concrete.

Regular:

Finish quality depends on carpenter/formwork skill.

Variable curing may reduce long-term durability.

10. Risk Management

Precast:

Factory safety: Reduced fall/electrical risks.

Site risks: Crane operations, lifting errors.

Regular:

Onsite hazards: Formwork collapses, wet concrete handling, rebar impalement.

When to Choose Which

| Scenario | Preferred Method | Why |

|---|---|---|

| Tight urban site | Precast | Less onsite activity; faster assembly |

| Custom organic architecture | Regular concrete | Flexible formwork for curves/unique shapes |

| High-rise cores | Hybrid (precast + cast-in-place) | Precast walls + cast-in-place joints for seismic resilience |

| Remote location | Regular concrete | Avoid transport/logistics costs |

| Repetitive structures (parking, schools) | Precast | Mass production cuts costs/time |