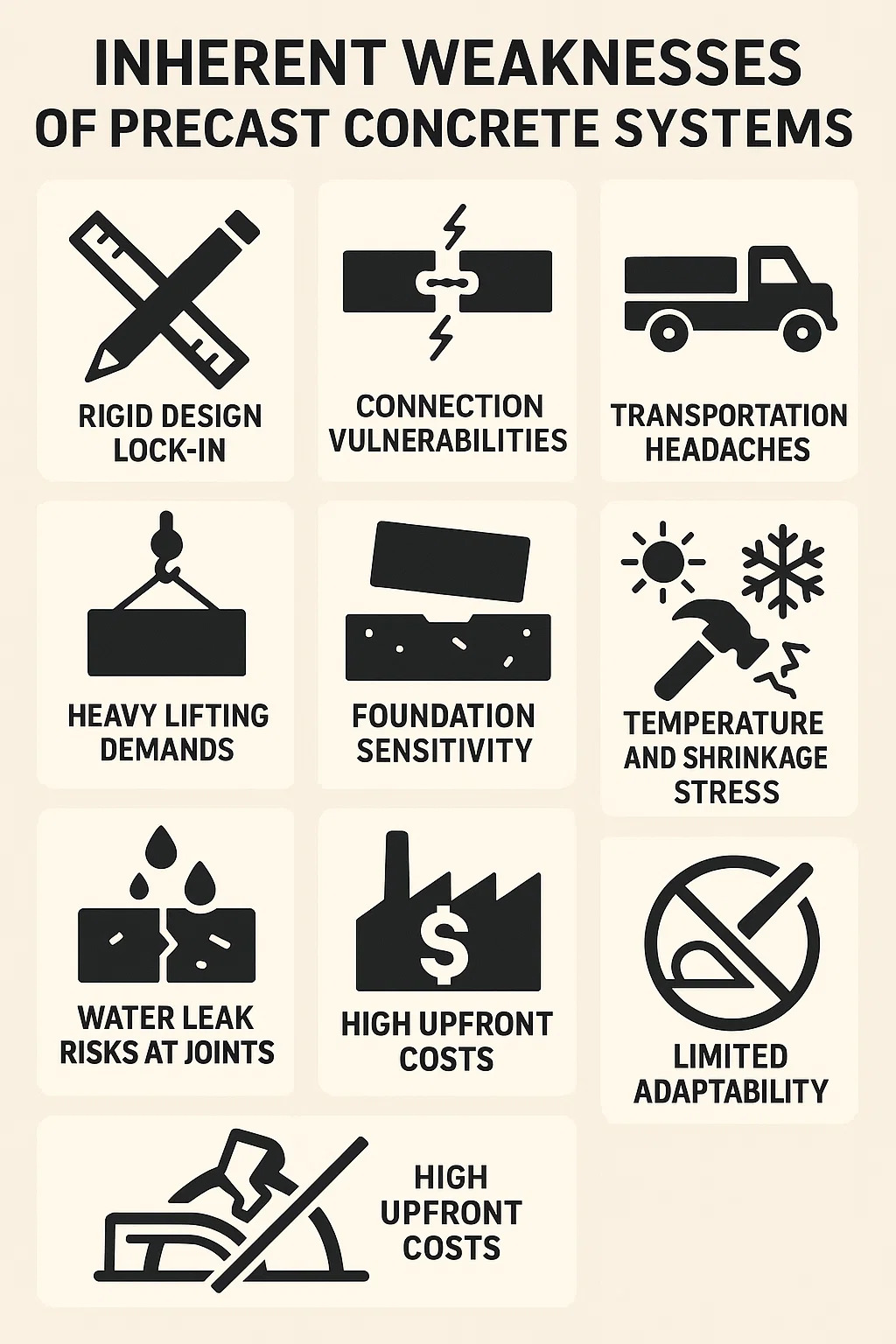

Here are the inherent weaknesses of precast concrete systems:

Content

●Rigid Design Lock-In

Once pieces are cast in the factory, you can't change their size, shape, or features. Any design tweaks require new molds, causing delays and extra costs.

●Connection Vulnerabilities

The joints where pieces bolt or glue together are weak spots. If connections aren't perfect, structures can develop cracks or shift under stress, especially in earthquakes or high winds.

●Transportation Headaches

Big, heavy pieces need special trucks, permits, and routes. Tight turns, low bridges, or bad roads can damage panels or girders before they reach the site.

●Heavy Lifting Demands

You need big cranes and skilled crews to set pieces in place. Sites with tight spaces or poor access might struggle with logistics.

●Foundation Sensitivity

If the foundation isn't perfectly level or anchors are off by even a little, precast pieces won't fit. Fixing this means costly adjustments or recasting parts.

●Temperature and Shrinkage Stress

Concrete shrinks as it cures. When multiple pieces connect, uneven shrinking can pull joints apart or cause cracks over time.

●Water Leak Risks at Joints

Seals between panels can fail, letting water seep into buildings or parking structures. This demands ongoing maintenance to prevent damage.

●High Upfront Costs

Custom molds and factory production cost more upfront than traditional formwork. You need repeat designs or large projects to justify the expense.

●Repair Difficulty

Damaged pieces (e.g., from impacts or rusted rebar) are hard to fix onsite. Often, you must replace the whole unit, which is slow and expensive.

●Limited Adaptability

Precast works poorly for unique, curved, or complex designs. Sites needing frequent design changes should avoid it.