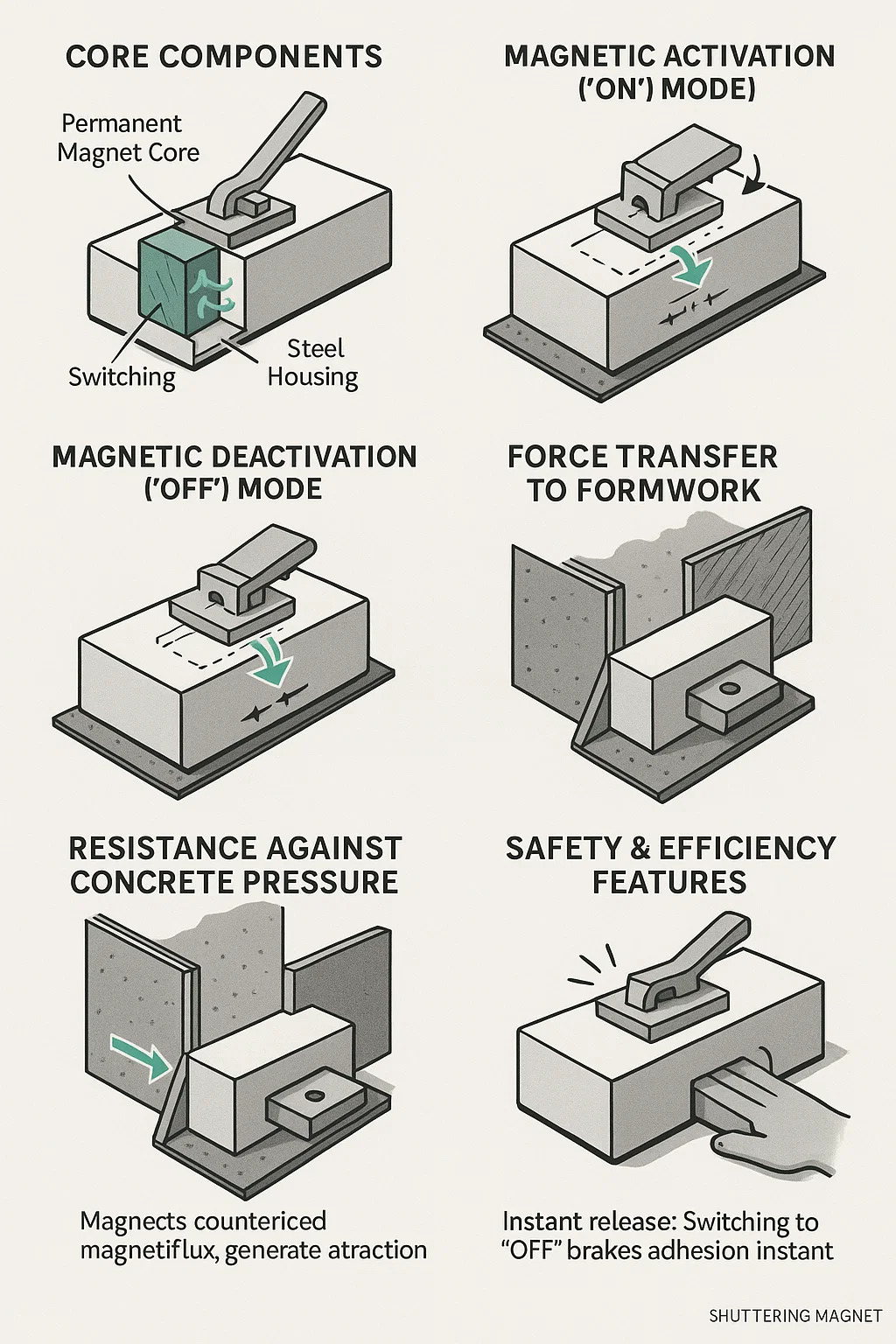

Shuttering Magnet Working Mechanism

Shuttering magnets operate through controlled magnetic force to secure concrete formwork. Here’s a step-by-step breakdown of their functionality:

1. Core Components

Permanent Magnet Core: Made of high-strength materials (e.g., neodymium) that generate a fixed magnetic field.

Steel Housing: Encases the magnet, directing and amplifying magnetic flux toward the contact surface.

Switching Mechanism: A lever or button that shifts internal steel plates to redirect the magnetic field.

2. Magnetic Activation ("ON" Mode)

When the switch is engaged, internal steel plates align to channel magnetic flux outward.

The magnetic field flows through the steel housing → contacts the steel formwork → creates a closed magnetic circuit.

Result: Strong magnetic adhesion locks the formwork panels together.

3. Magnetic Deactivation ("OFF" Mode)

Flipping the switch repositions internal plates to create a short-circuit path inside the magnet.

Magnetic flux is rerouted internally, bypassing the contact surface.

Result: External magnetic force drops to near zero, allowing easy removal.

4. Force Transfer to Formwork

The magnet's contact surface must attach to ferromagnetic materials (steel forms or embedded plates).

Magnetic flux penetrates the steel, generating attraction proportional to:

Magnet strength.

Contact area flatness.

Absence of rust/debris.

5. Resistance Against Concrete Pressure

During pouring, liquid concrete exerts lateral pressure on forms.

Magnets counteract this by:

Distributing force along the steel form's surface.

Preventing formwork separation or "blowouts."

6. Safety & Efficiency Features

Instant Release: Switching to "OFF" breaks adhesion instantly.

No Residual Magnetism: Unlike electromagnets, permanent types leave no lingering field after deactivation.

Physical Handling: Grooves/handles prevent fingers from contacting pinch points during placement.

| Component / Phase | Function / Action | Result / Effect |

| Core Magnet | Permanent high-strength magnet (e.g., neodymium) generates constant magnetic flux. | Creates foundational magnetic field contained within the housing. |

| Steel Housing | Channels and concentrates magnetic flux toward the contact surface. | Amplifies magnetic force at the interface with steel formwork. |

| Switching Mechanism | Lever or button shifts internal steel plates. | Controls the path of magnetic flux (ON: outward / OFF: internal loop). |

| ON State (Activation) | Plates align to direct flux through housing → formwork. | Magnetic circuit closes: Strong adhesion secures formwork panels. |

| OFF State (Deactivation) | Plates reroute flux into internal short-circuit loop. | External field collapses: Magnet releases instantly with near-zero residual force. |

| Force Transfer | Requires direct contact with steel formwork or embedded ferrous materials. | Magnetic flux penetrates steel, creating clamping force proportional to contact. |

| Concrete Pressure | Liquid concrete exerts outward pressure against forms during pouring. | Magnet resists blowout by distributing force along steel form’s surface. |

| Workflow: Placement | Clean, rust-free steel surface identified; magnet positioned flush against formwork. | Ensures maximum force transfer; prevents slippage. |

| Workflow: Activation | Switch engaged → flux channeled outward. | Forms locked rigidly in alignment. |

| Workflow: Removal | Switch disengaged after concrete sets → flux contained internally. | Magnet detaches cleanly; ready for reuse with no damage to forms or concrete. |

| Critical Limitation | Only bonds to ferromagnetic surfaces (steel forms/plates). | Ineffective on wood, plastic, or aluminum formwork systems. |