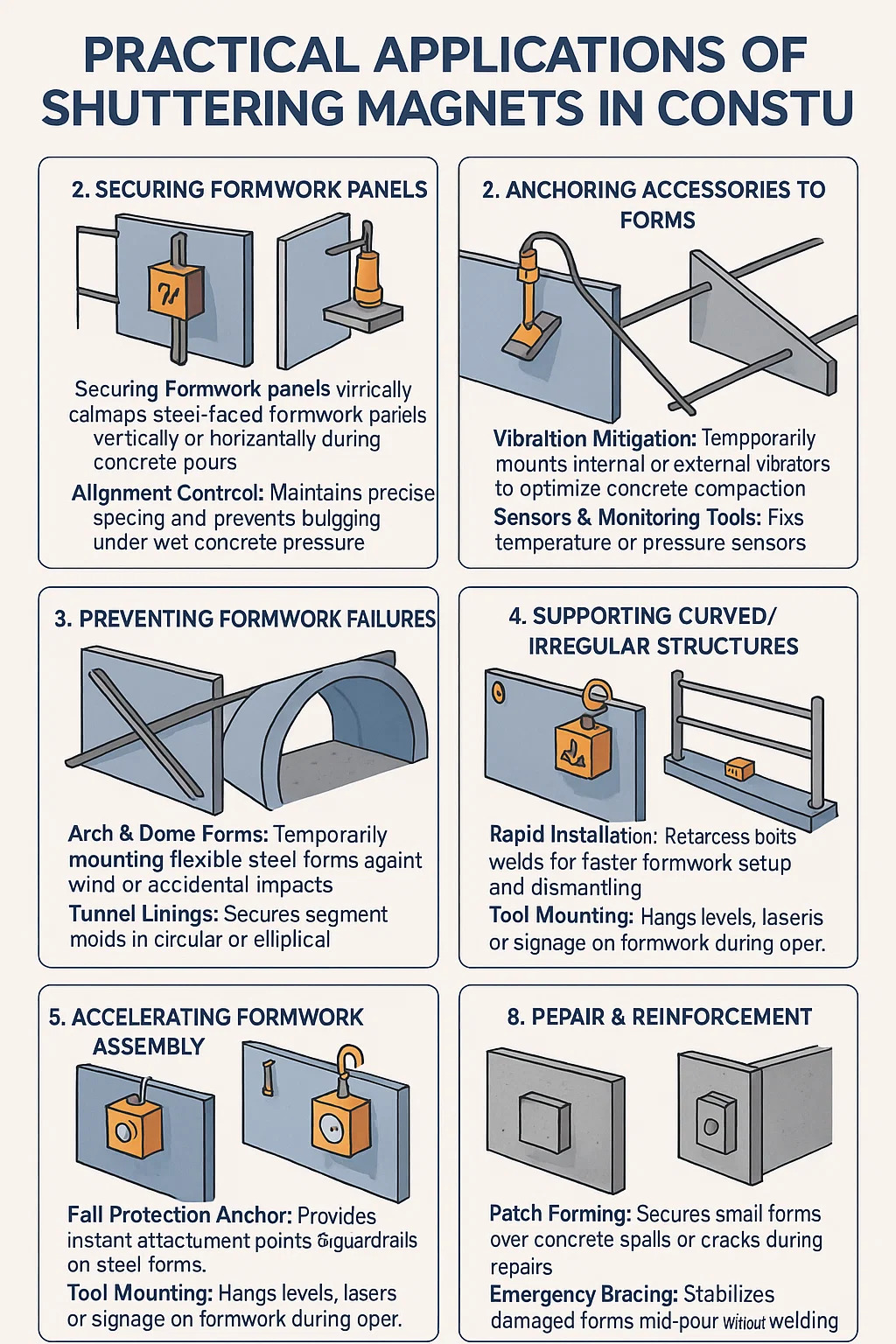

Practical Applications of Shuttering Magnets in Construction

1. Securing Formwork Panels

Wall & Column Forms: Clamps steel-faced formwork panels vertically or horizontally during concrete pours.

Alignment Control: Maintains precise spacing and prevents bulging under wet concrete pressure.

Junction Reinforcement: Locks corner joints and T-sections where forms meet.

2. Anchoring Accessories to Forms

Vibration Equipment: Temporarily mounts internal or external vibrators to optimize concrete compaction.

Conduits & Embedded Parts: Holds electrical conduits, anchor bolts, or dowel sleeves in position prior to pouring.

Sensors & Monitoring Tools: Fixes temperature or pressure sensors to track concrete curing.

3. Preventing Formwork Failures

Blowout Mitigation: Reinforces high-stress zones (e.g., deep foundations, thick walls) resisting burst pressure.

Lateral Bracing: Stabilizes free-standing forms against wind or accidental impacts.

4. Supporting Curved/Irregular Structures

Arch & Dome Forms: Clamps flexible steel forms to molds for complex geometries.

Tunnel Linings: Secures segmental molds in circular or elliptical tunnel projects.

5. Accelerating Formwork Assembly

Rapid Installation: Replaces bolts/welds for faster formwork setup and dismantling.

Reusable Fixtures: Attaches lifting eyes or temporary handles to forms for crane maneuvers.

6. Temporary Safety & Site Operations

Fall Protection Anchor: Provides instant attachment points for guardrails on steel forms.

Tool Mounting: Hangs levels, lasers, or signage on formwork during operations.

7. Precast Concrete Production

Mold Assembly: Aligns and clamps mold sections for precast units (e.g., beams, panels).

Fixture Positioning: Holds inserts or embeds in molds without drilling.

8. Repair & Reinforcement

Patch Forming: Secures small forms over concrete spalls or cracks during repairs.

Emergency Bracing: Stabilizes damaged forms mid-pour without welding.

| Application Category | Specific Use Case | Operational Value |

| Formwork Securing | Vertical wall panel alignment | Locks steel-faced forms flush during concrete pour; prevents misalignment |

| Column form bracing | Reinforces circular/square column molds against bursting pressure | |

| Beam soffit support | Holds suspended bottom forms in place without scaffolding | |

| Accessory Mounting | Concrete vibrator attachment | Temporarily fixes internal/external vibrators to optimize consolidation |

| Embedded item positioning | Secures conduit pipes, anchor sleeves or lifters prior to casting | |

| Safety & Temporary Works | Fall protection anchor points | Instantly creates guardrail tie-offs on steel forms at height |

| Tool/signage hanging | Mounts levels, warning signs or drawings during operations | |

| Complex Geometry Works | Curved wall form retention | Clamps flexible steel liners for arches/radial structures |

| Tunnel segment molds | Fixes precast tunnel lining forms during assembly | |

| Precast Production | Mold clamping | Aligns and seals mold sections for beams/wall panels without bolts |

| Fixture retention | Holds inserts, lifting eyes or embeds in molds | |

| Repair & Adaptation | Emergency form patching | Secures repair forms over cracks/spalls mid-construction |

| Formwork modification | Temporarily adds bracing or extensions to existing forms |