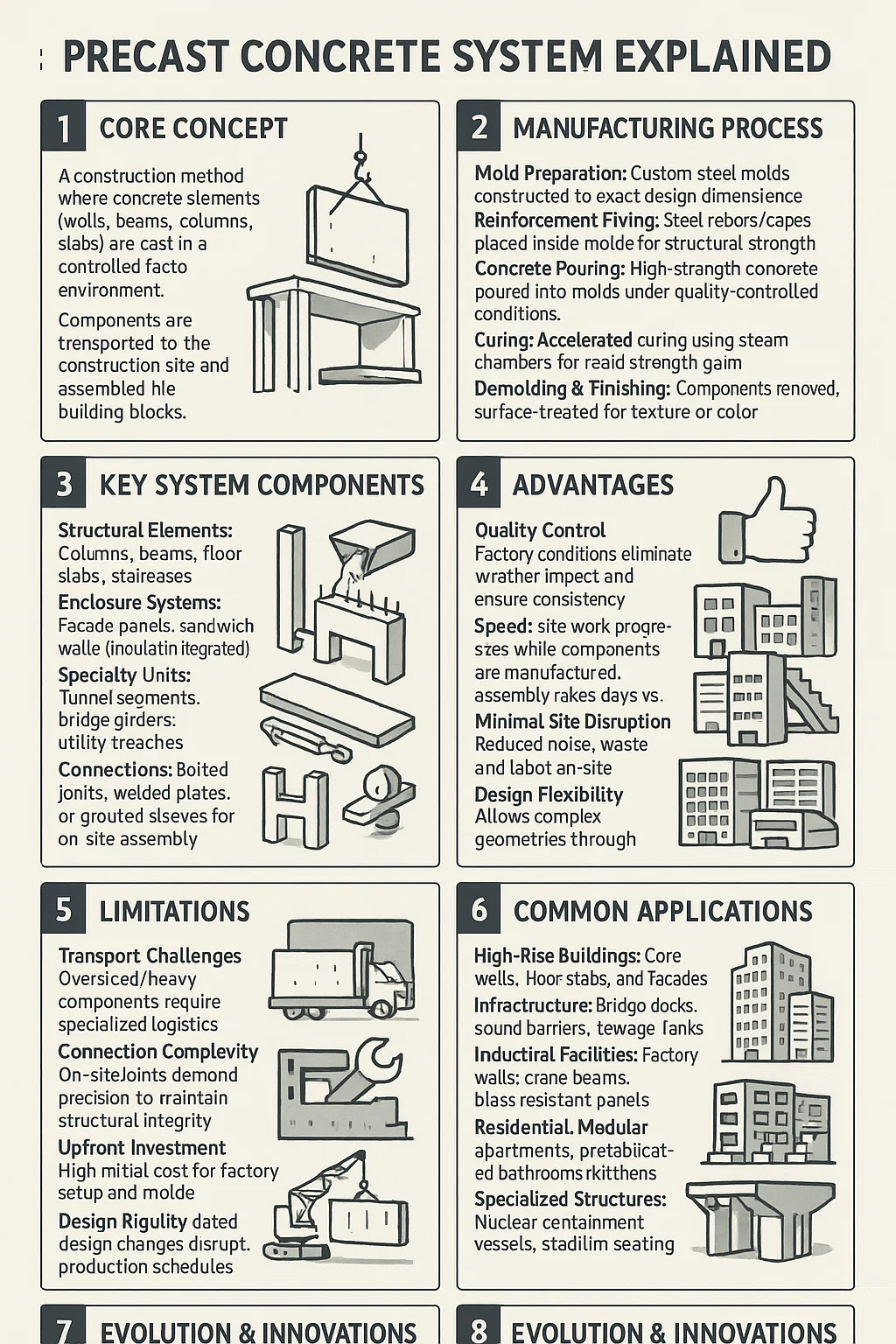

Precast Concrete System Explained

1. Core Concept

A construction method where concrete elements (walls, beams, columns, slabs) are cast in a controlled factory environment.

Components are transported to the construction site and assembled like building blocks.

2. Manufacturing Process

Mold Preparation: Custom steel molds constructed to exact design dimensions.

Reinforcement Fixing: Steel rebars/cages placed inside molds for structural strength.

Concrete Pouring: High-strength concrete poured into molds under quality-controlled conditions.

Curing: Accelerated curing using steam chambers for rapid strength gain.

Demolding & Finishing: Components removed, surface-treated for texture or color.

3. Key System Components

Structural Elements: Columns, beams, floor slabs, staircases.

Enclosure Systems: Façade panels, sandwich walls (insulation integrated).

Specialty Units: Tunnel segments, bridge girders, utility trenches.

Connections: Bolted joints, welded plates, or grouted sleeves for on-site assembly.

4. Advantages

Quality Control: Factory conditions eliminate weather impact and ensure consistency.

Speed: Site work progresses while components are manufactured; assembly takes days vs. weeks.

Minimal Site Disruption: Reduced noise, waste, and labor on-site.

Design Flexibility: Allows complex geometries through custom molds.

Durability: Higher density concrete with optimized curing resists cracks/corrosion.

5. Limitations

Transport Challenges: Oversized/heavy components require specialized logistics.

Connection Complexity: On-site joints demand precision to maintain structural integrity.

Upfront Investment: High initial cost for factory setup and molds.

Design Rigidity: Late design changes disrupt production schedules.

6. Common Applications

High-Rise Buildings: Core walls, floor slabs, and façades.

Infrastructure: Bridge decks, sound barriers, sewage tanks.

Industrial Facilities: Factory walls, crane beams, blast-resistant panels.

Residential: Modular apartments, prefabricated bathrooms/kitchens.

Specialized Structures: Nuclear containment vessels, stadium seating.

7. Site Assembly Workflow

Foundation Prep: Cast foundations with embedded connectors.

Component Delivery: Sequence trucks by assembly order.

Lifting & Placement: Cranes position elements onto bearings/connectors.

Structural Connections: Weld plates, install bolts, or grout sleeves.

Sealing & Finishing: Waterproof joints and apply final finishes.

8. Evolution & Innovations

Hybrid Systems: Combining precast with cast-in-place for complex joints.

Digital Integration: BIM models guide mold design and assembly sequencing.

Sustainability: Recycled aggregates and low-carbon cement in mixes.