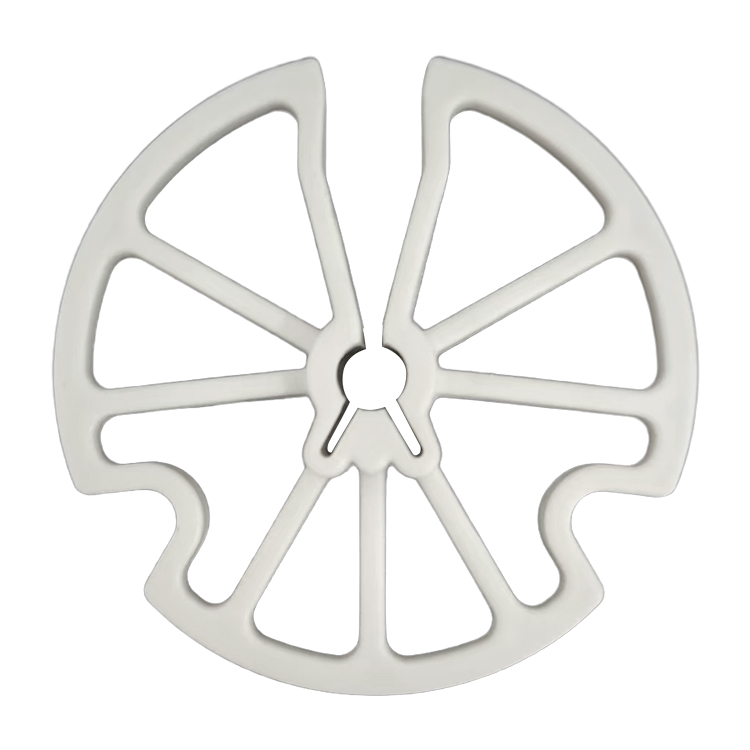

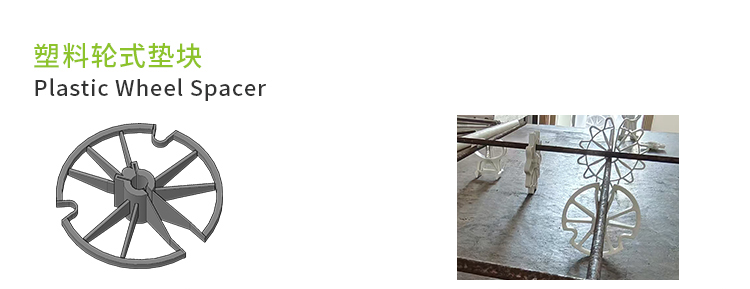

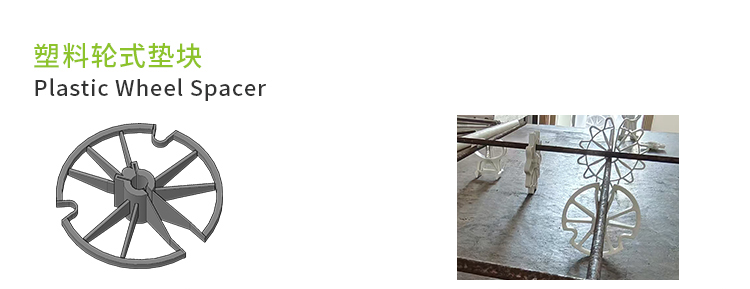

Specifications of Concrete Plastic Wheel Spacer

|

Model

|

Cover of Concrete(mm)

|

For Bar Dia(mm)

|

|

WWPH-B1

|

20

|

6-8mm

|

|

WWPH-B2

|

25

|

6-12mm

|

|

WWPH-B3

|

30

|

6-8mm

|

|

Other size on request

|

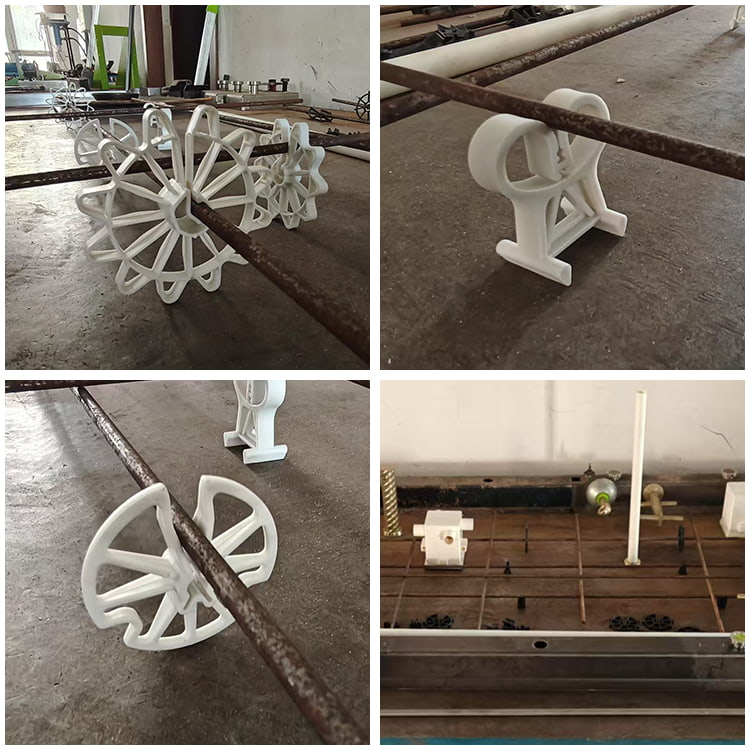

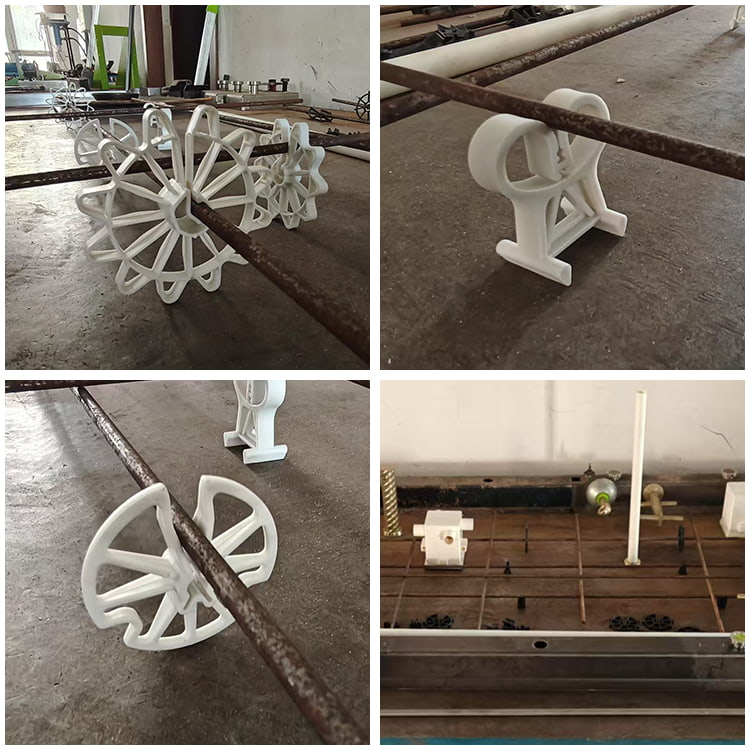

Key Features of Concrete Plastic Wheel Spacer

High-Strength Materials:

Plastic concrete spacers are made from premium polypropylene (PP) or polyethylene (PE), offering high compressive strength and durability to withstand the pressure of concrete pouring. Unlike steel, the plastic material will not rust or deform, making it ideal for use in humid, acidic, or alkaline environments.

Lightweight & Easy Installation:

Concrete plastic spacers are lightweight, easy to transport, and simple to install. They reduce construction time and labor costs while ensuring convenient on-site handling.

Available in Multiple Specifications:

Our plastic spacers are available in a variety of cover heights and diameters to meet different structural requirements. Whether for slabs, beams, columns, or precast elements, we provide customized spacer sizes tailored to your application.

Environmentally Friendly & Recyclable:

Made from recyclable materials, these spacers meet environmental standards and help minimize their environmental impact.

Applications of Concrete Plastic Wheel Spacer

The plastic wheel spacer is suitable for:

1. Precast concrete walls and panels

2. Columns and vertical reinforcement

3. Tunnels, pipes, and culverts

4. Civil engineering and infrastructure projects

5. Foundations and retaining walls

Whether used in construction sites or precast factories, the Concrete Plastic Wheel Spacer ensures stability, safety, and quality for every concrete structure.

Why Choose Our Factory

Strong Customization Capability:

We specialize in customized production according to customer drawings, samples, or technical requirements.

From mold design to mass production, we provide flexible solutions for various precast concrete accessories, ensuring perfect fit and performance for every project.

One-Stop Solution for Precast Concrete Accessories:

We offer a complete range of precast concrete products, including lifting anchors, magnetic formwork systems, rebar spacers, and fixing components.

Our one-stop supply chain helps clients save time, reduce cost, and ensure consistent quality across all accessories.

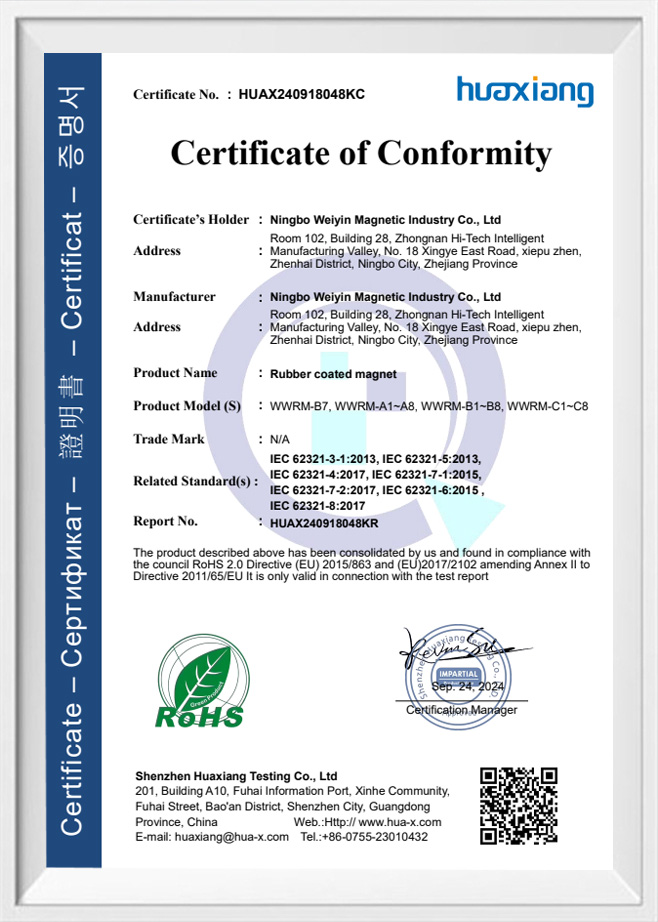

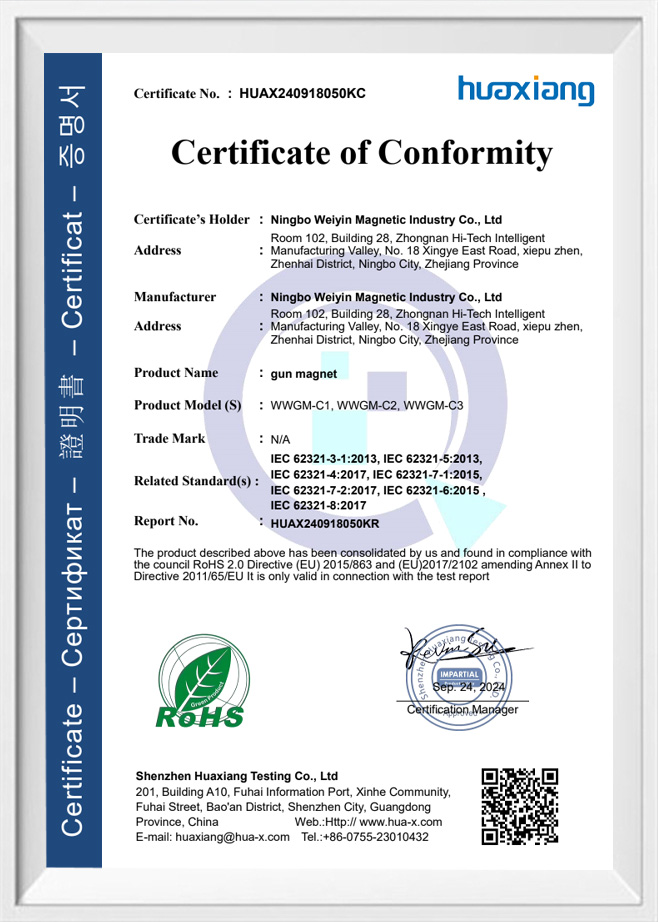

Professional Manufacturing & Quality Assurance:

With advanced injection molding and forging equipment, strict quality control, and ISO-certified management, we guarantee stable performance, high strength, and long service life of all our products.

Each item is tested before shipment to meet international construction standards.

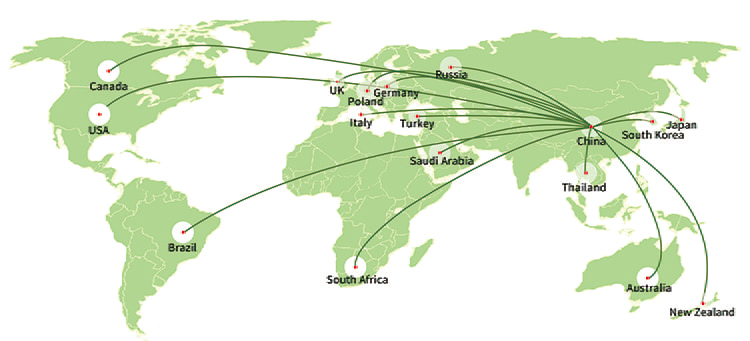

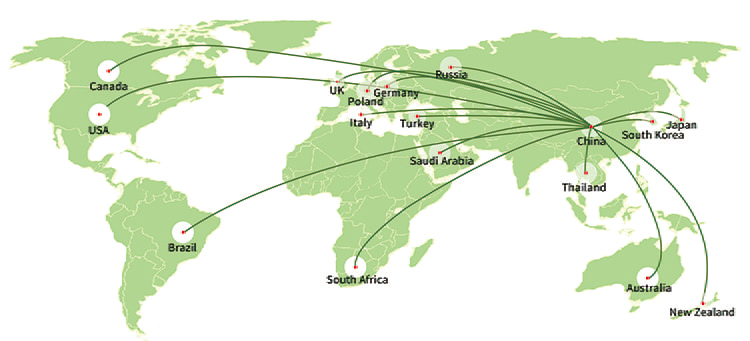

Reliable Partner with Global Experience:

We have extensive export experience serving customers in Europe, the Middle East, and Asia, providing technical support and after-sales service.

Our factory is committed to building long-term partnerships with global clients by delivering high-quality products and professional solutions.