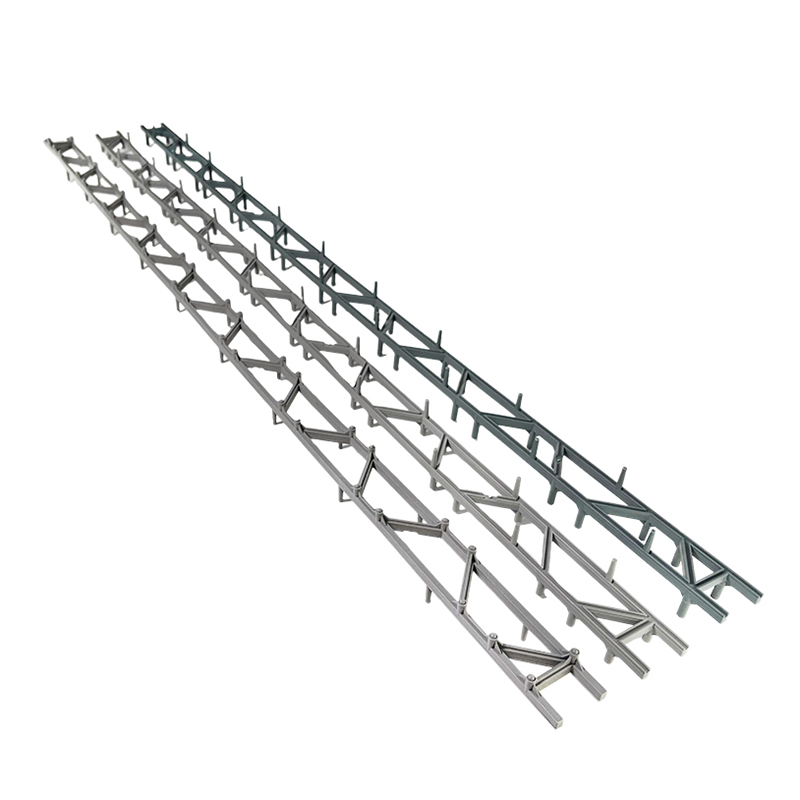

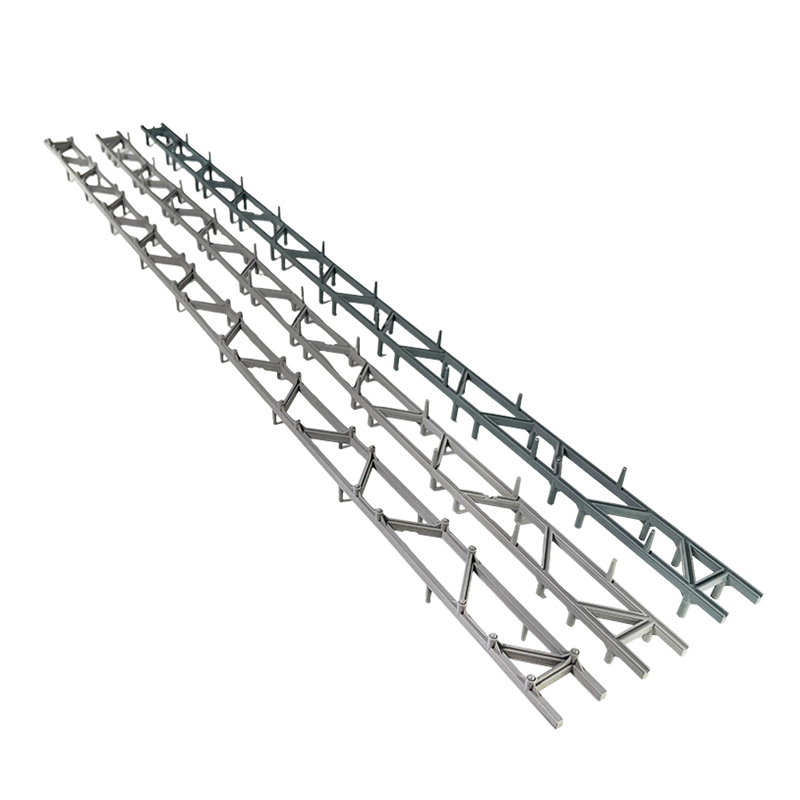

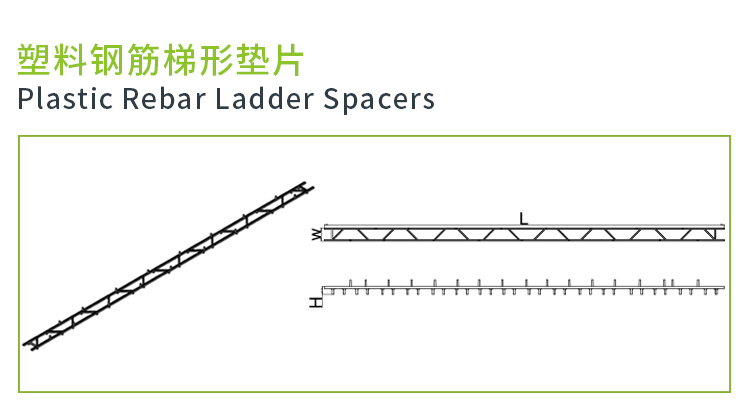

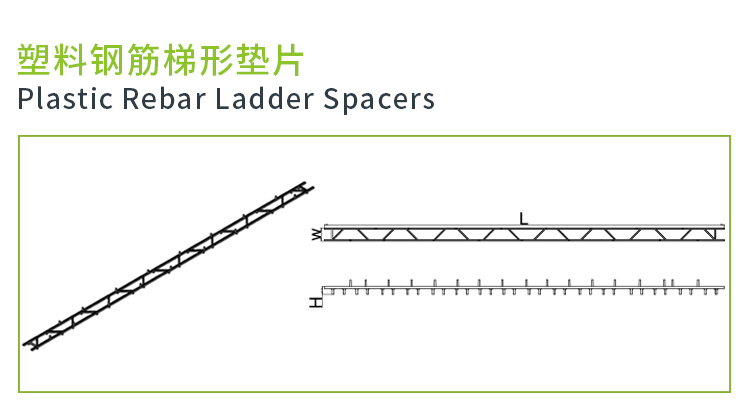

Specifications of Plastic Rebar Ladder Spacer

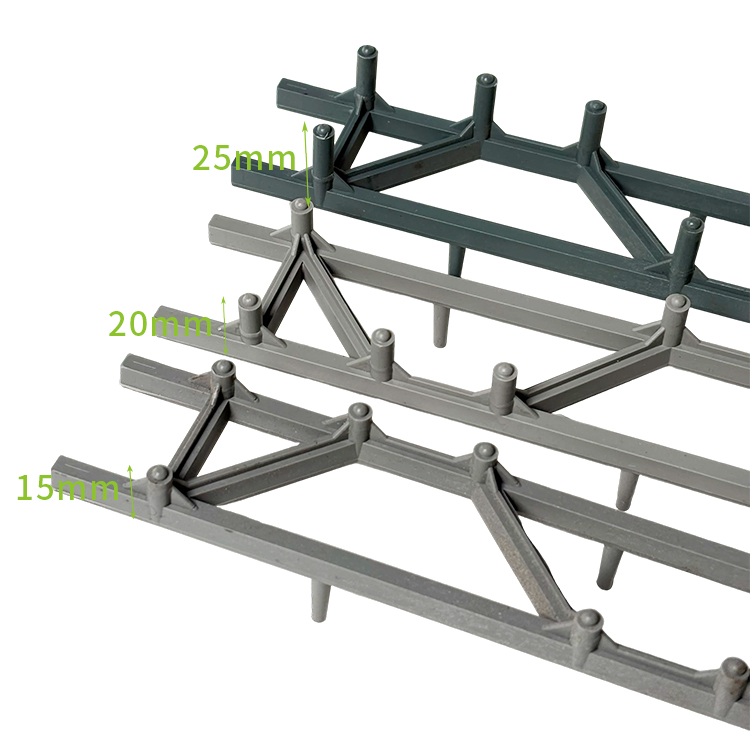

| Model |

L(mm) |

W(mm) |

H(mm) |

Weight(g) |

| WWSA-l1 |

1000 |

35 |

15 |

87 |

| WWSA-l2 |

1000 |

35 |

20 |

93 |

| WWSA-13 |

1000 |

35 |

25 |

105 |

| Other size on request |

Key Features

1. High Strength & Stability:

Ensures accurate spacing between rebar layers, maintaining structure integrity.

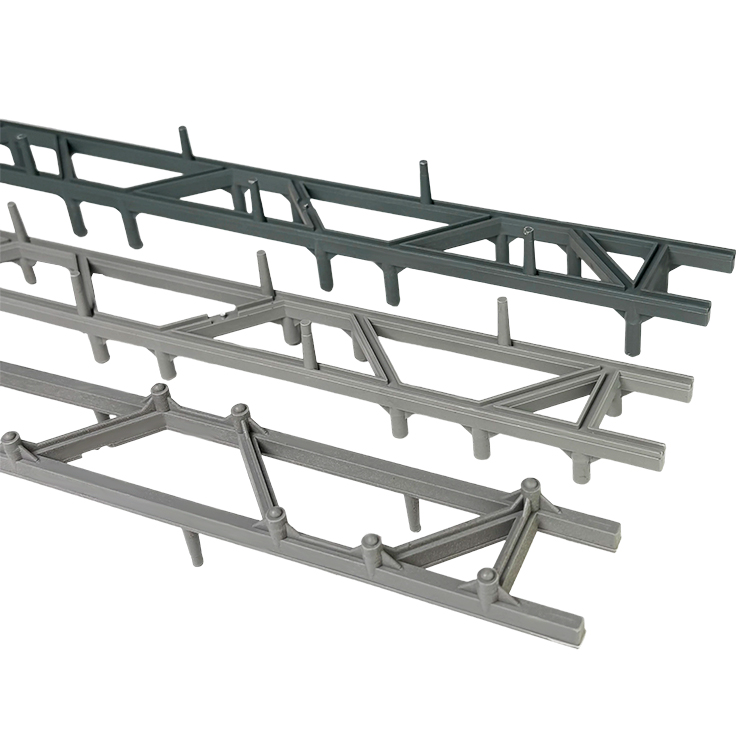

2. Corrosion & Chemical Resistant:

Made from tough, weatherproof plastic that resists concrete alkali and corrosion.

3. Easy to Use:

Lightweight and easy to install on reinforcement meshes, saving time and labor on site.

4. Efficient Ladder Design:

Allows smooth concrete flow and strong bonding around the reinforcement.

5. Wide Application:

Perfect for slabs, beams, precast panels, foundations, and bridge decks.

6. Cost Effective Solution:

Reusable and long-lasting, reducing waste in large construction projects.

Applications

1. Plastic Rebar Ladder Spacers are widely used in:

2. Precast concrete elements (walls, beams, panels, slabs)

3. Cast-in-place concrete floors and foundations

4. Industrial and civil building structures

5. Infrastructure projects such as bridges, tunnels, and roads

They help maintain the designed concrete cover between rebar layers, preventing steel corrosion and ensuring structural durability.

How to Use

Place the Plastic Ladder Spacer horizontally between two layers of reinforcing steel mesh.

Adjust the position to maintain uniform spacing across the slab or precast form.

Pour concrete directly over the reinforcement — the ladder spacer will hold its shape and position throughout the pour.

Why Choose Our Factory?

1. Over 10 years of manufacturing experience in concrete accessories

2. OEM/ODM service available — customized size, logo, and packaging

3. Strict quality control and fast delivery

4. One-stop solution for precast concrete products