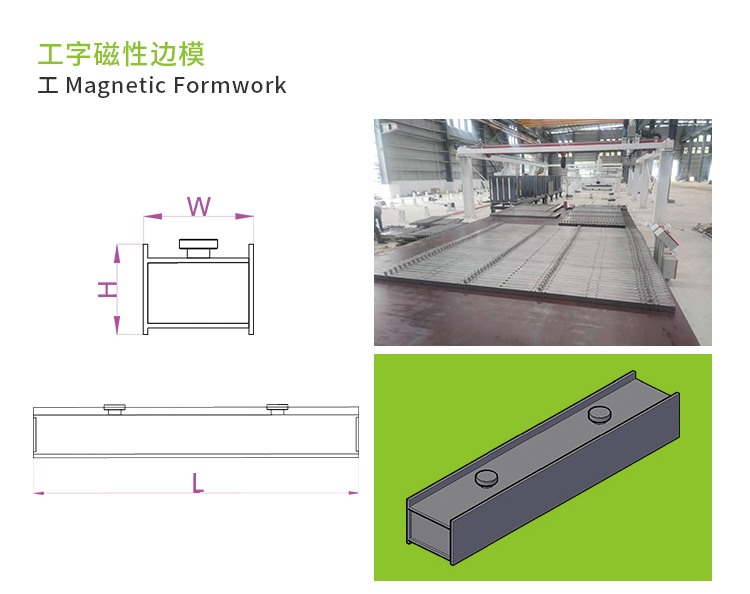

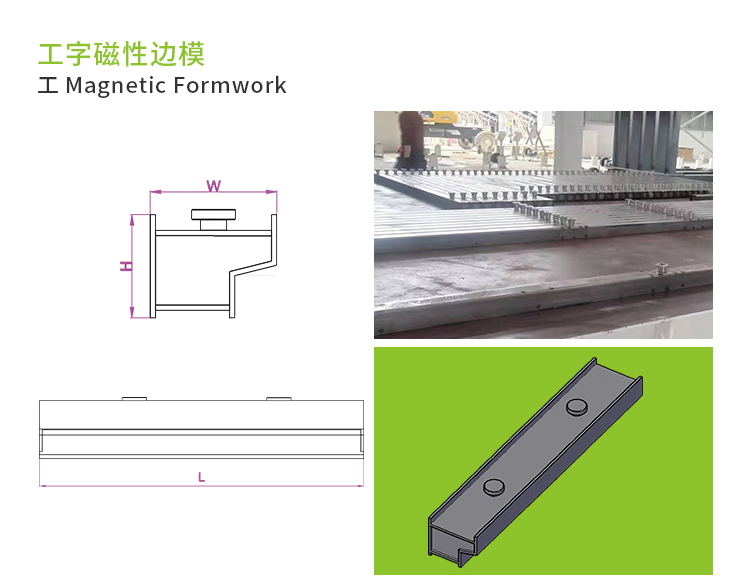

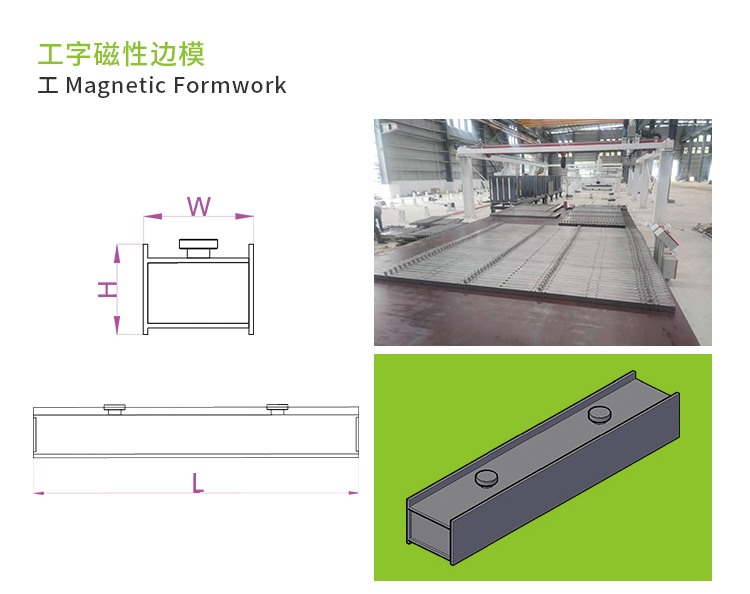

Specifications of Magnetic Formwork

| Model |

L(mm) |

W(mm) |

H(mm) |

Weight(kg) |

Pull Force(kg) |

| WWMFB-A1 |

500 |

130 |

98 |

10.3 |

2100kg*1 |

| WWMFB-A2 |

1000 |

20.8 |

2100kg*2 |

| WWMFB-A3 |

1400 |

24.8 |

| WWMFB-A4 |

2000 |

33.6 |

| WWMFB-A5 |

2500 |

39.6 |

| WWMFB-A6 |

3000 |

49.3 |

2100kg*3 |

| WWMFB-A7 |

3700 |

56.6 |

| Other size on request |

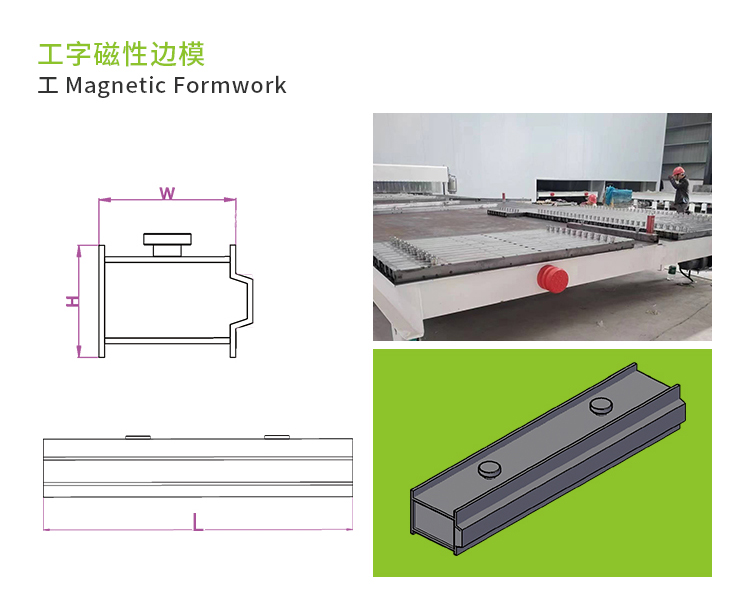

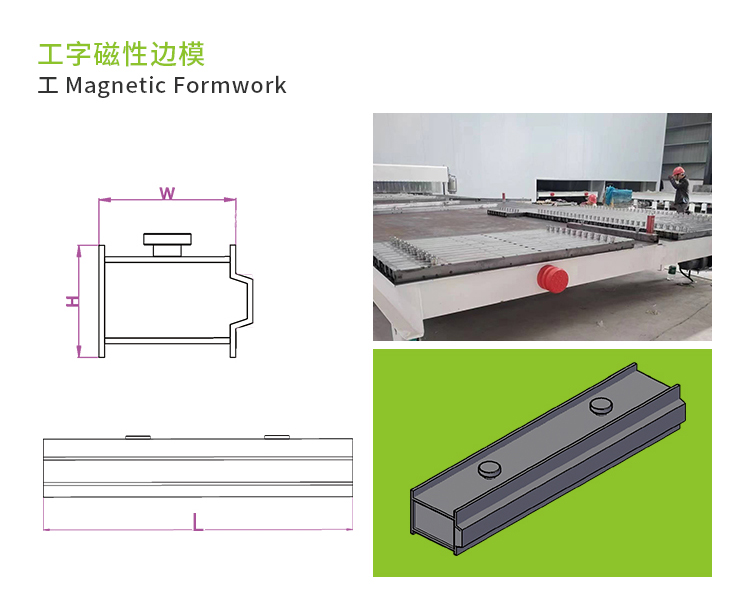

| Model |

L(mm) |

W(mm) |

H(mm) |

Weight(kg) |

Pull Force(kg) |

| WWMFB-B1 |

500 |

130 |

98 |

10.8 |

2100kg*1 |

| WWMFB-B2 |

1000 |

21.6 |

2100kg*2 |

| WWMFB-B3 |

1400 |

26.4 |

| WWMFB-B4 |

2000 |

35.2 |

| WWMFB-B5 |

2500 |

41.8 |

| WWMFB-B6 |

3000 |

52.8 |

2100kg*3 |

| WWMFB-B7 |

3700 |

59.6 |

| Other size on request |

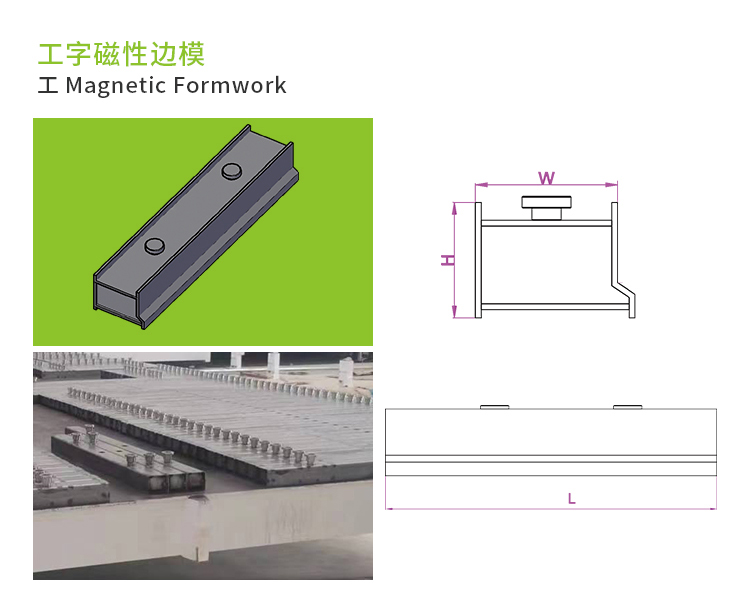

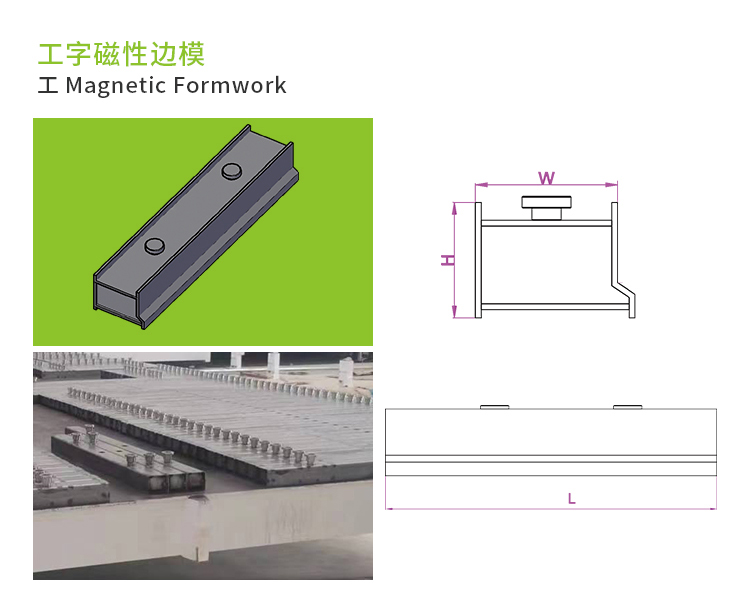

| Model |

L(mm) |

W(mm) |

H(mm) |

Weight(kg) |

Pull Force(kg) |

| WWMFB-C1 |

500 |

130 |

98 |

10.5 |

2100kg*1 |

| WWMFB-C2 |

1000 |

21.2 |

2100kg*2 |

| WWMFB-C3 |

1400 |

25.6 |

| WWMFB-C4 |

2000 |

34.7 |

| WWMFB-C5 |

2500 |

40.8 |

| WWMFB-C6 |

3000 |

50.7 |

2100kg*3 |

| WWMFB-C7 |

3700 |

58.2 |

| Other size on request |

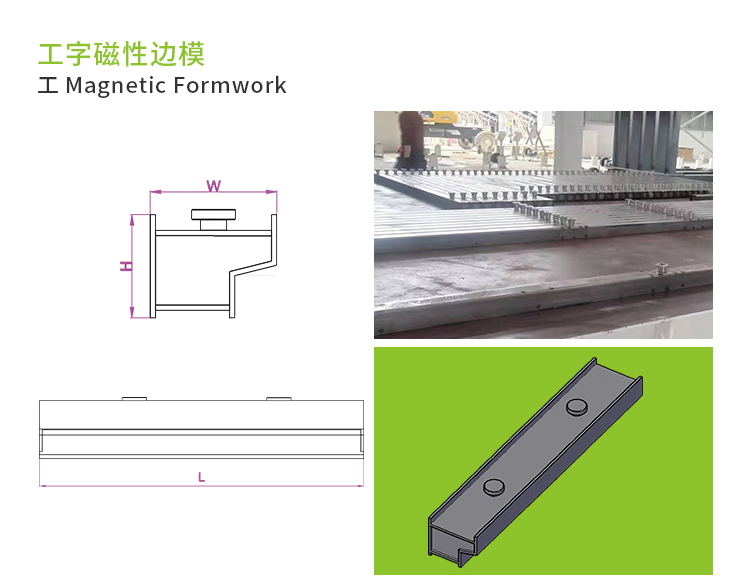

| Model |

L(mm) |

W(mm) |

H(mm) |

Weight(kg) |

Pull Force(kg) |

| WWMFB-D1 |

500 |

130 |

98 |

10.3 |

2100kg*1 |

| WWMFB-D2 |

1000 |

20.8 |

2100kg*2 |

| WWMFB-D3 |

1400 |

24.8 |

| WWMFB-D4 |

2000 |

33.6 |

| WWMFB-D5 |

2500 |

39.6 |

| WWMFB-D6 |

3000 |

49.3 |

2100kg*3 |

| WWMFB-D7 |

3700 |

56.6 |

| Other size on request |

Applications

1. Precast wall panels

2 .Solid and sandwich panels

3. Precast slabs and beams

4. Custom concrete elements with straight edges

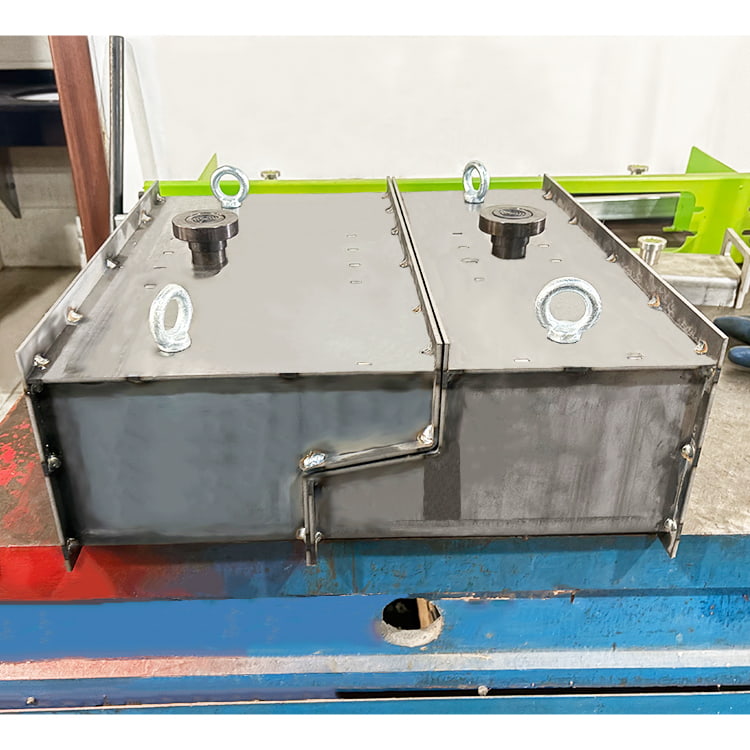

Through the adhesion of the magnetic block, the formwork is in close contact with the formwork, so that the formed formwork system is fixed, thereby fixing the formwork system to be formed. Since the steel formwork and the magnet are integrated, there will be no position shifting and the formwork system will not be deformed. At the same time, the simple and fast operation of the magnet makes the entire work safer and more stable.

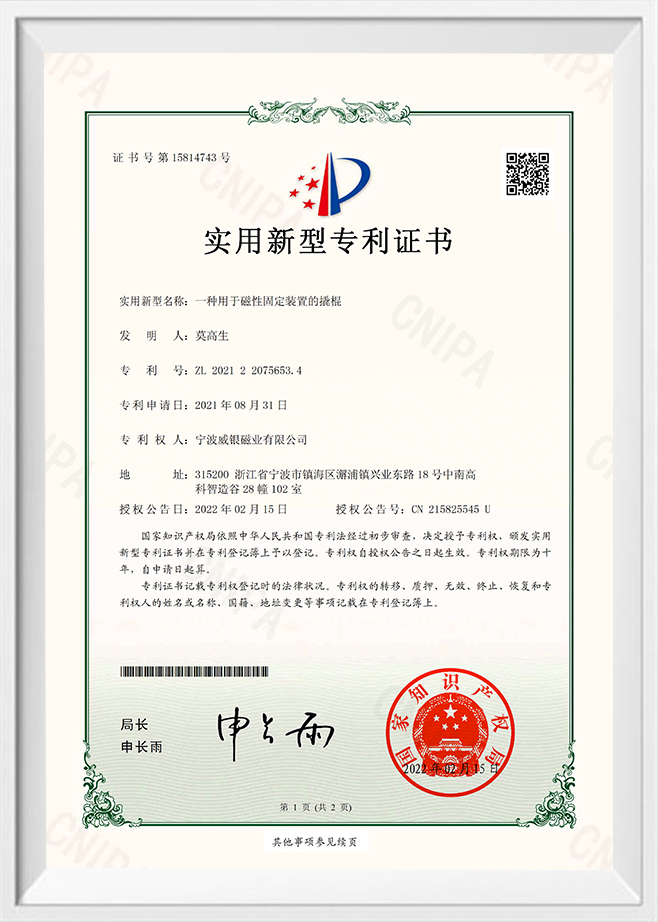

Using the matching crowbar, the formwork magnet can be picked up and the steel formwork can be easily removed from the formwork. Since the magnet is located in the steel formwork slot, concrete residues or other dirt will not cause damage to the entire formwork system. Other sizes can be manufactured on request.

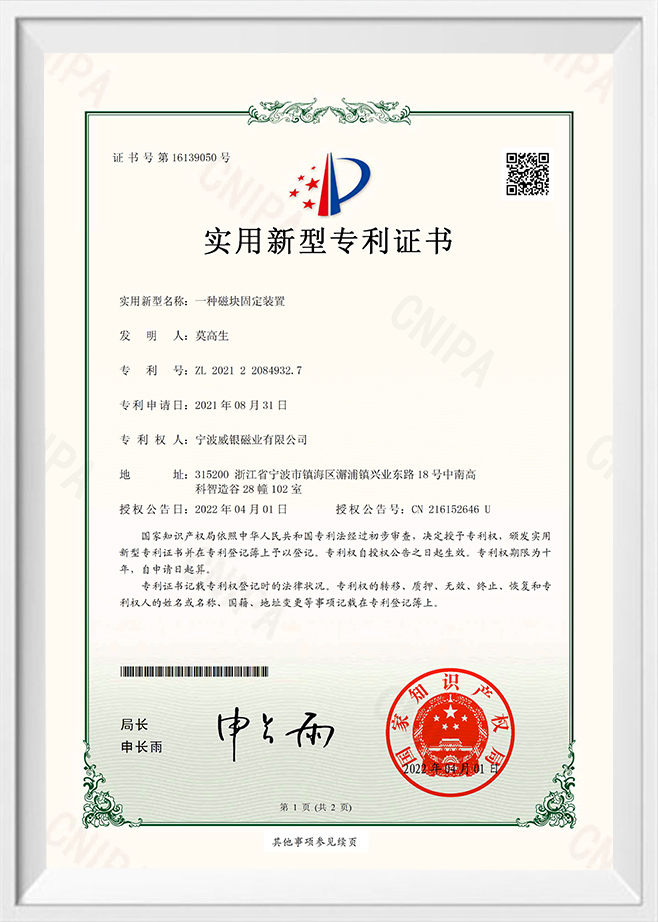

Package of Formwork Magnet

Our packaging can be customized according to customer needs. We will make magnetic isolation packaging for every magnetic product. The packaged products will reach your hands smoothly.

Why Choose Our Magnetic Formwork?

Compared with traditional bolted or welded formwork, this magnetic formwork system offers:

1. Faster setup

2. Higher dimensional accuracy

3. Reduced bed damage

4. Lower long-term operating cost

It is a proven solution for modern precast concrete production lines aiming at automation, standardization, and efficiency.

Looking for a custom magnetic formwork solution for your precast project?

Contact us for drawings, technical support, and quotation.