Built for precast work:

Magnetic formworks hold their shape under pressure and snap off clean when it is cured whether casting wall panels, beams, or hollow cores.

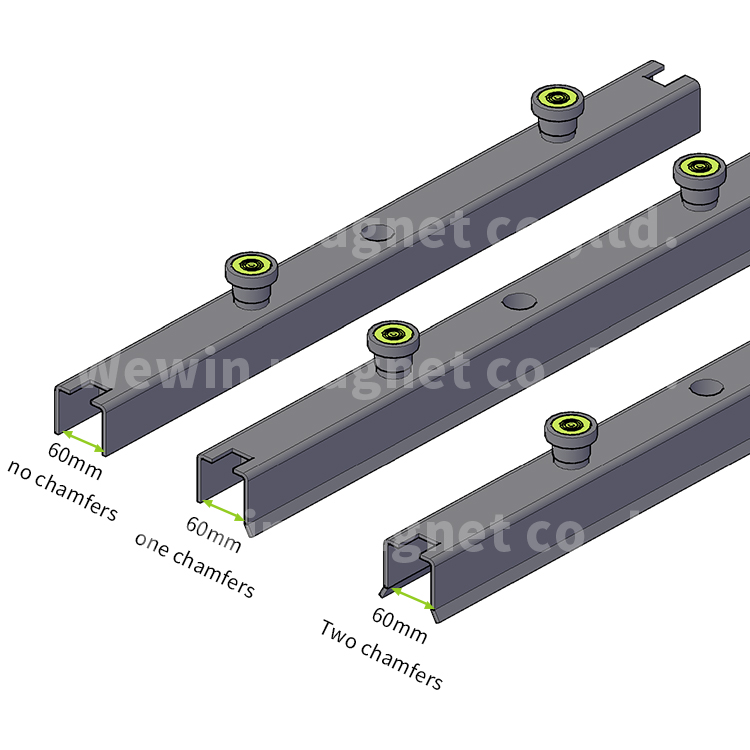

Specification of Magnetic Formwork:

| Model |

L(mm) |

W(mm) |

H(mm) |

Weight(kg) |

Pull Force(kg) |

| WWMFA-A1 |

500 |

60 |

70 |

5.2 |

600kg*2 |

| WWMFA-A2 |

810 |

6.5 |

| WWMFA-A3 |

1000 |

7.2 |

| WWMFA-A4 |

1200 |

8.4 |

| WWMFA-A5 |

1400 |

11.5 |

900kg*2 |

| WWMFA-A6 |

2500 |

16.5 |

| WWMFA-A7 |

3000 |

19.8 |

900kg*3 |

| WWMFA-A8 |

3500 |

22.8 |

| Other size on request |

| Model |

L(mm) |

W(mm) |

H(mm) |

Weight(kg) |

Pull Force(kg) |

| WWMFA-B1 |

500 |

60 |

70 |

5.2 |

600kg*2 |

| WWMFA-B2 |

810 |

6.5 |

| WWMFA-B3 |

1000 |

7.2 |

| WWMFA-B4 |

1200 |

8.4 |

| WWMFA-B5 |

1400 |

11.5 |

900kg*2 |

| WWMFA-B6 |

2500 |

16.5 |

| WWMFA-B7 |

3000 |

19.8 |

900kg*3 |

| WWMFA-B8 |

3500 |

22.8 |

| Other size on request |

| Model |

L(mm) |

W(mm) |

H(mm) |

Weight(kg) |

Pull Force(kg) |

| WWMFA-C1 |

500 |

60 |

70 |

5.2 |

600kg*2 |

| WWMFA-C2 |

810 |

6.5 |

| WWMFA-C3 |

1000 |

7.2 |

| WWMFA-C4 |

1200 |

8.4 |

| WWMFA-C5 |

1400 |

11.5 |

900kg*2 |

| WWMFA-C6 |

2500 |

16.5 |

| WWMFA-C7 |

3000 |

19.8 |

900kg*3 |

| WWMFA-C8 |

3500 |

22.8 |

| Other size on request |

How to use it:

-Need to put the formwork at the required positions on steel casting bed.

-Press on the magnet button with lever– it is done and locked in.

-Cast the concrete as usual.

-Remove the formwork after curing process by pulling the button with lever — then transfer it to mold.

The advantages of magnetic formwork:

-Improves the speed of production line – no tools or clamps required.

-Reusable, reusable and reusable again – just clean and reset.

-Magnet-based – no surface damage and unnecessary fixing work.

-Polished edges, every time an option for chamfer profiles.

-Tough built – quality steel and high-grade magnets.

Why magnetic formwork is important:

When it comes to time, in precast construction, time is actually money. The faster production line moves — and the more it looks the same when it is done — the tighter prep-work, pour-work, and demold-work. The magnetic formwork is not only making effort easy – it is making quality standard, cutting labor costs and adding life to equipment.

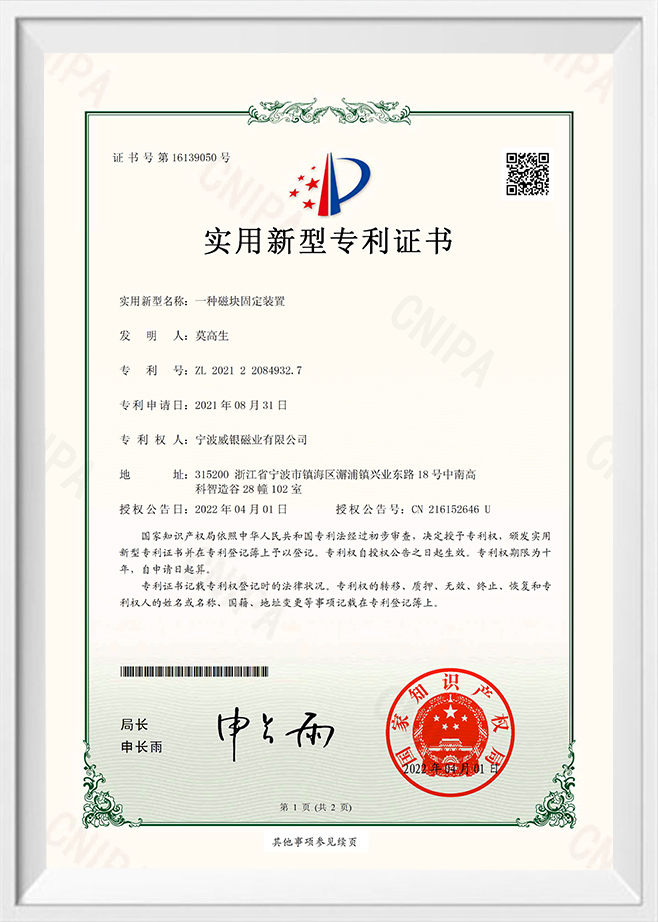

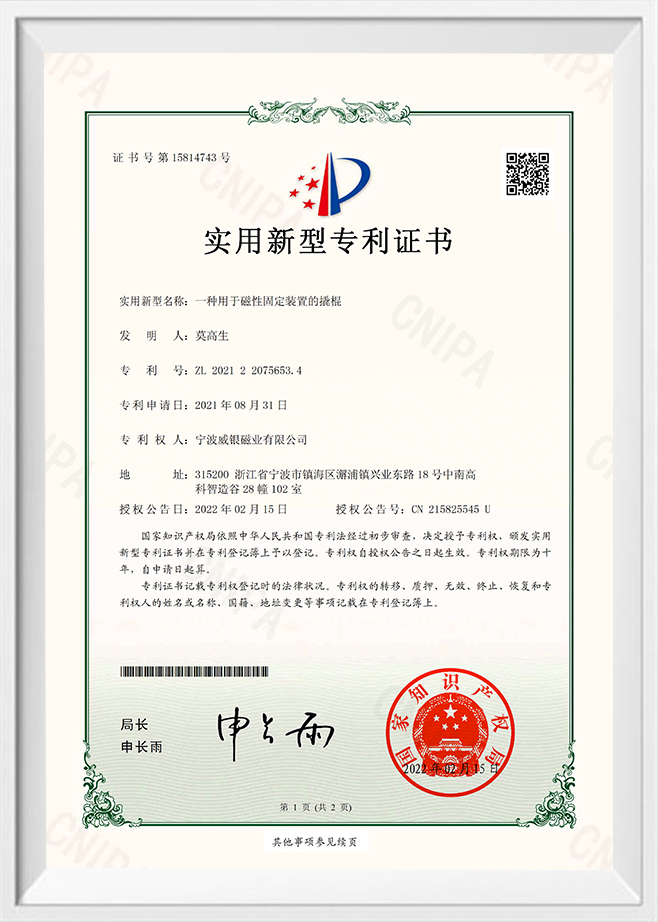

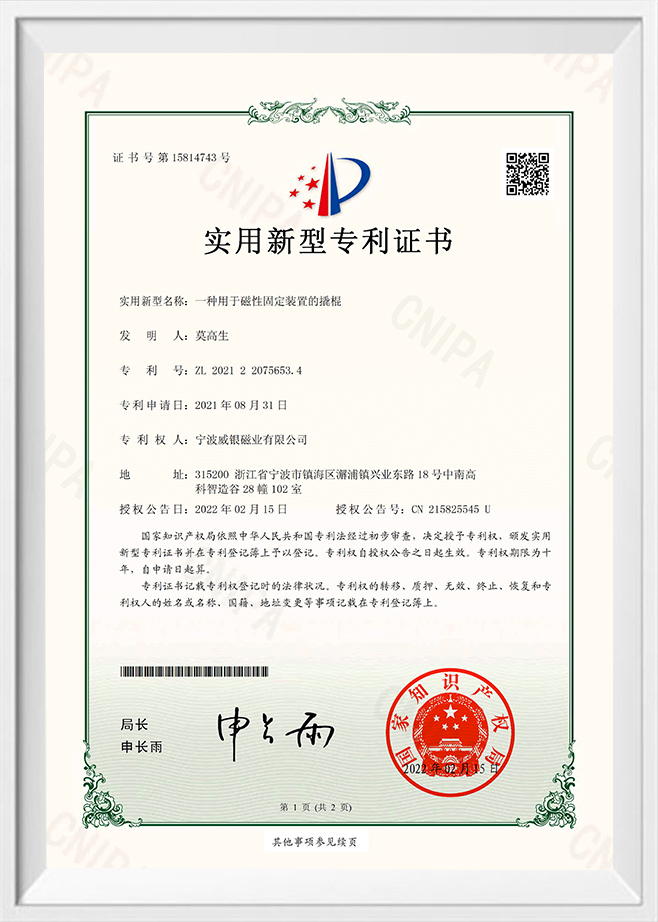

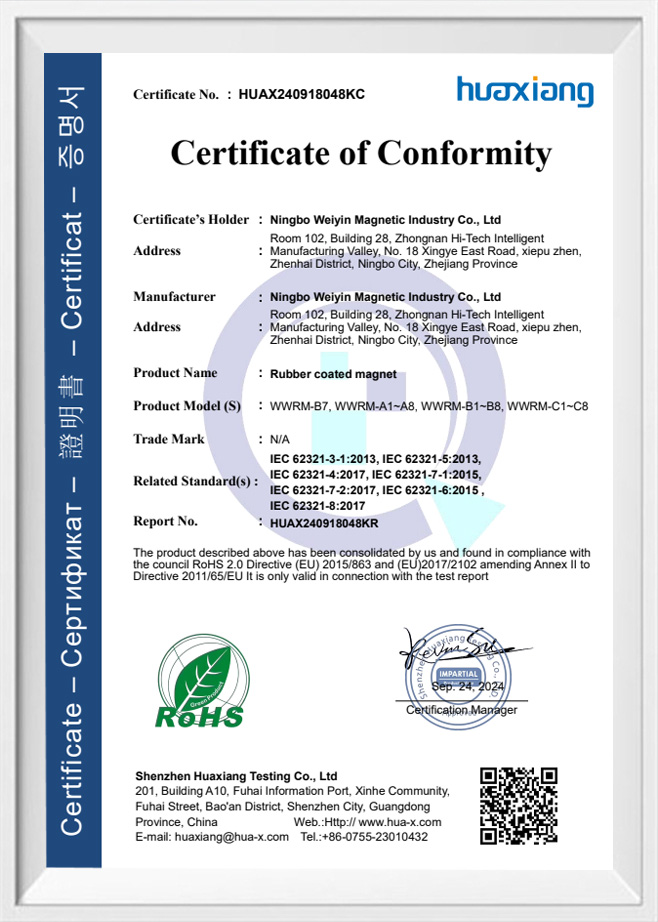

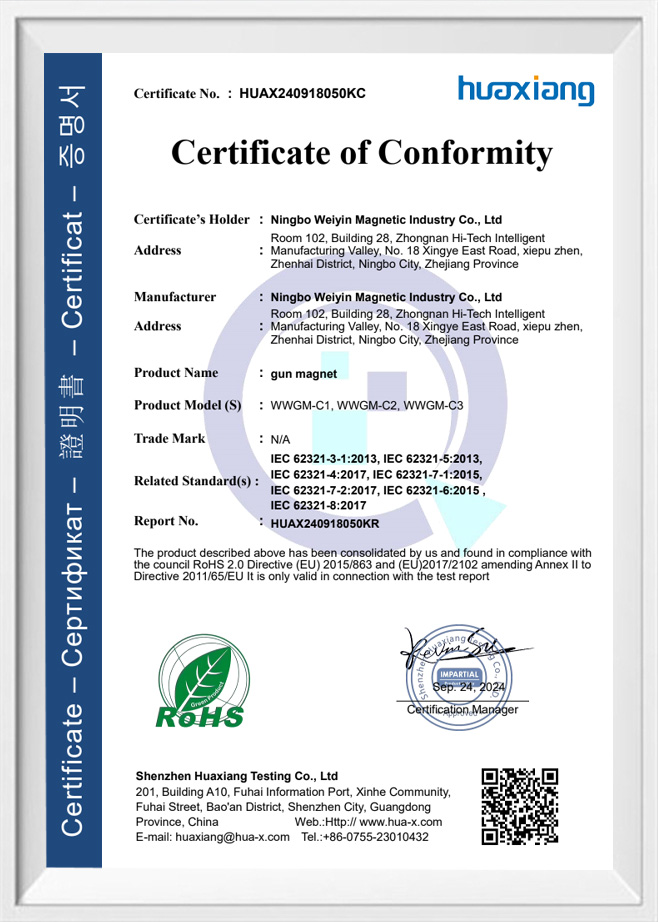

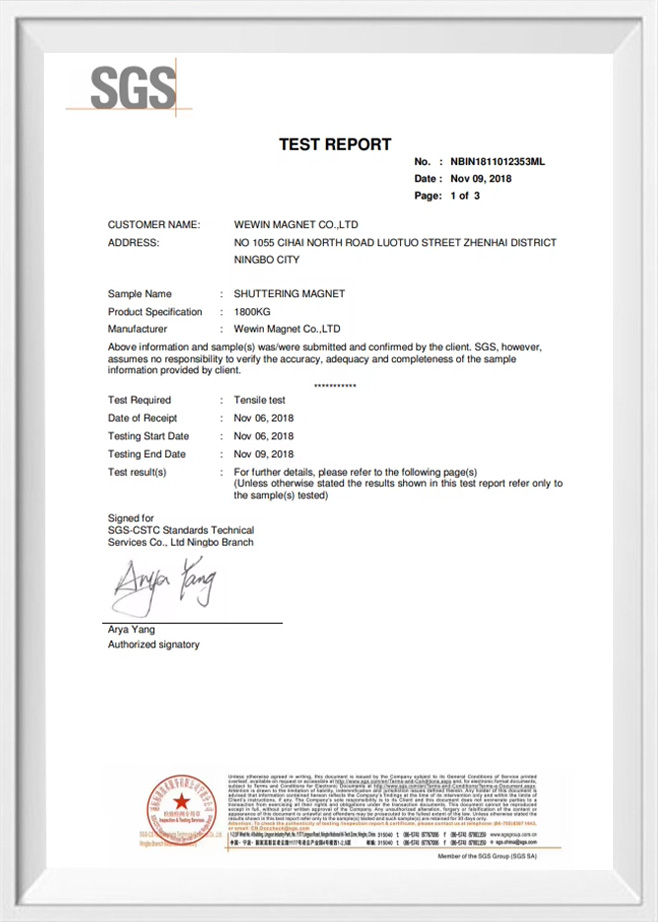

Why Wewin Magnet?

We are not only a Magnet supplier – we are a partner in the smart precast production. From made to measure to OEM branding, our team is on hand to help you from concept to installation.

-Fast production & delivery

-Strict quality control

-Expert technical support

-Reliable worldwide in the concrete factories & formwork specialists’ environments.

Coming to a Conclusion

All things considered; the magnetic formwork used by Wewin is a real game changer for precast concrete. Formwork is easier to install and remove with systems from BS, saving work hours and expenses. Thanks to their strong magnetism, these shuttering magnets help keep everything immobile, even when poured-in concrete makes things messy. Bricks can also be cast using a variety of materials for formwork, no matter if it’s wood, aluminum or steel. Should you want to streamline and simplify your precast projects, consider using Wewin’s tools. They lessen the effort needed and help keep your work of high quality. If you’re involved in construction, maybe give these magnets a test.

Popular Questions

What does magnetic formwork consist of?

While constructing, magnetic formwork keeps concrete molds straight with the help of strong magnets. It becomes more convenient to both construct and remove the molds.

What advantages come from applying Wewin magnetic formwork?

Wewin system formwork is simple and easy to apply. Such material has strong attraction, can be modified for various tasks and is built to last.

In which applications do we find magnetic formwork?

Creating wall panels and slabs is easy with the help of magnetic formwork. VSS can be used successfully with different materials used in construction.

How are Wewin’s products made to retain their quality?

Wewin employs top materials and rigorous testing to ensure what they create matches industry requirements.

How does Wewin help its customers with their needs?

Wewin provides assistance, directions and special solutions to help customers maximize their products’ use.

Where does the trend in construction move with precast?

Area trends include the development of innovative formwork, special consideration of environmental concerns and expanding the role of precast construction.